Making a Sheet Metal AK47 Receiver - March 16th, 2017

Last year I machined an AR15 lower from a solid forging, so I thought it was only fair to give communism equal opportunity. So I bought a Hungarian AK63D underfolder parts kit for a winter project and got to work. I've never even held an AK before, so I'm sure there will be a lot to figure out along the way.

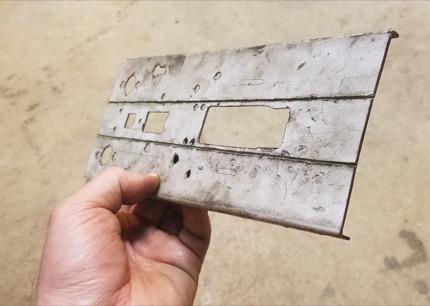

I drew this flat pattern with CAD software after tons of research and measuring the torch cut receiver pieces. It's pasted onto a piece of .050" 4130 sheet metal.

The holes are drilled and the receiver is cut out. If you have a portable bandsaw and haven't made a stand for it, you're missing out. A metal cutting bandsaw is a seriously handy tool in the workshop.

Next I Dremeled and filed out the holes to the proper shape. In retrospect, it probably would have been better to do the mag well after bending. The narrow edge didn't want to bend that easily.

I stuck the rails in a vice on the bend lines and beat them over with a hammer. Make sure your vice jaws have a crisp edge for best results. Then I scored the next set of bend lines with a cutoff wheel about 75% the way through. After that, I could bend it by hand. I did have to persuade the narrow part by the mag well a bit with a hammer.

With the receiver bent, I cut out the sections of rail so the trunnions would fit.

Then I clamped the receiver to a piece of 1.25" square tubing and welded up the seam.

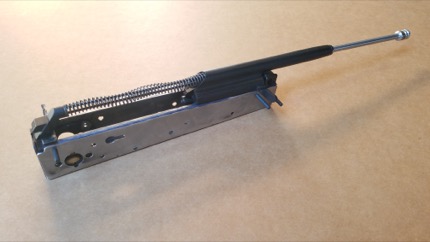

Here's the receiver welded up and sanded smooth. Then I drilled holes for the trunnion rivets and tested the bolt carrier. It took some filing and grinding on the rails to get the bolt carrier to slide smoothly.

The receiver completed. I cut out clearance in the rails so I can install the bolt carrier and bolt once the trunnions have been riveted on.

I spot welded the grip reinforcing plate before installing the trunnions while I still had access.

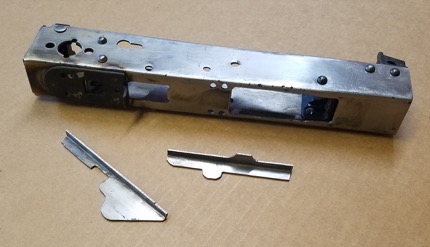

Next I riveted the trunnions in. I made a cupped backing plate to keep the rounded head of the rivet from getting flattened, and I also made a pressing tool from a piece of 3/4" hot rolled round bar. Most people make these from grade 8 bolts which is a far better idea. I had to straighten my tool out after every rivet, but this was the best material I could find in the scrap bin.

Both trunnions are riveted on. I put this off for a while because I thought it'd be harder than it actually was.

Here's my simple riveting tools. The 3/4" bar has a glob of weld on the end that I shaped into a pad to press the rivets. It's important to press the rivets below the journal the barrel presses into in the front trunnion, so the pad can't be too big.

Next I removed the pins from the barrel components and pressed them off the stubs of barrel. Some of these pins were impossible to budge, so I had to mill them out.

Here's how I populated the barrel. First I pressed the rear sight base on just enough to get it started. Then I slipped on the handguard holder and I pressed the gas block into position. I measured from the center of the hole in the gas block to the edge and marked that distance from the gas port in the barrel. Then I pressed the gas block on until the edge was even with the line. That means the hole in my gas block is centered with the hole in the barrel. After that was established, I pressed on the front sight and finished pressing the rear sight block until the upper handguard could lock in place. Getting everything clocked accurately has been left as an exercise to the reader.

Next I made the lower rails out of the same .050" 4130 sheet metal.

Then I drilled some holes through the side and welded them in place. I used a drill bit that's the right diameter to align the lower rails with the slots in the front trunnion.

Next I pressed the barrel into the front trunnion and disaster struck. The gas piston jammed against the gas tube and the bolt carrier jammed against the rear sight block. Somehow my barrel ended up ~.025" too low and tilted downwards, despite the front trunnion being parallel with the rails. After thinking it over I decided the easiest fix would be cut the rivets off, clamp the trunnion in place so the piston works, and then weld it. It's not ideal, but I made sure to keep the locking lugs cool and only weld a little bit at a time. I didn't take a picture of this step because I was pretty peeved.

Once I had the front trunnion welded so the gas piston slid easily, I headspaced the barrel. I chambered my go gauge and pressed the barrel down until it bottomed out. Then I checked it with the no go gauge and it was perfect.

Then I milled out the pin holes and pinned on the barrel components.

Just so the ATF doesn't kick down my door and shoot my dog, I did buy enough US made parts for 922r compliance. The barrel is US made as is obviously the receiver.

Now to figure out how all this stuff goes back in!

All done! I put a couple coats of clear finish on the receiver so it will match the homemade look of my AR.

And in the folded position. It feels like this would be super awkward to shoot, although after watching a few tutorials on Youtube, the proper technique seems to be holding it above your head and screaming Aloha Snackbar.

I'm trying to think of what parts kit would be cool to build next. Suomi? Sten? Uzi? Someday I'd like to machine a 1911 frame from a forging.

Jefenry.com

Navigation

----------

----------

----------

----------

© 2008 - 2025 |  | RSS Feed

| RSS Feed

| RSS Feed

| RSS Feed