I do a lot of cutting and welding metal at work, and in November of 2013 it occurred to me that I could slip a pentagon into a waste section of a motor bracket we make and end up with enough pieces to make a dodecahedron since we get 12 brackets out of a 4' x 8' sheet of metal.

The angle between two faces of a dodecahedron is 116.56°, but I didn't use any jigs or protractors to align the faces. I found it easy enough to just hold the edges flush with each other. You can warp the pieces a bit if it's only tacked to get it into the right shape, and once the final face is tacked the sculpture will permanently hold its shape. Then I went back and fully welded the seams. Lots of grinding later I ended up with a useless piece of metal to put on my bookshelf.

So that was pretty cool, but I never made a page for this project since I didn't take any pictures as I went along as I was too excited to get the project done. However, I recently made a rather larger dodecahedron out of some scrap from another part and I made sure to take some shots of the process.

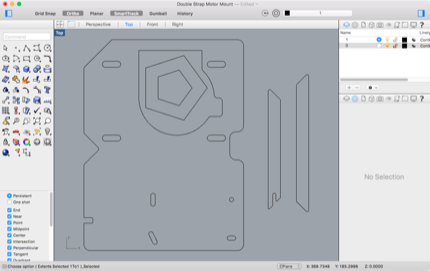

One of our products at work leaves a 20" x 48" section of the 4' x 8' sheet so I drew the largest pentagon that would fit and cut out 12 of them.

Our CNC plasma cutter makes short work of cutting stuff out. It took maybe 15 minutes to cut all 12 pentagons out. This is the same plasma cutter that I wrote a file to play Carol of the Bells.

The first three faces are the hardest to align since you need about four hands. It's easiest to tack the top of the two that are angled and then work on getting their edges flush to the one on the ground.

Work your way around the one on the ground making sure the edges are as flush as you can make them. Sloppy joints will follow you all the way to the top and it will be harder to make everything line up.

I found it easier to make two halves and then stack one on top of the other. On the little dodecahedron I worked my way to the top in one go and it got progressively harder. By making two halves they will sit on top of each other and I think it's easier to warp the pieces into position. Basically you end up with a zig zaggy equator to tack rather than trying to hold individual pieces in place.

And here's the project after welding. I didn't fully weld the seams, just in the corners and a small weld in the center of each edge.

It's pretty big! My boss plans to use it as a yard ornament or something. A few people think it might make a decent base to a coffee table too.

|

|